The Robotics Institute at Carnegie Mellon University created a new algorithmic planner that allocates jobs between people and robots in the most efficient way possible.

Determining who will perform specific activities as robots increasingly join people on the manufacturing floor, in warehouses, and everywhere on the job becomes more complicated and important. Some vocations require people, while others require robots. In certain circumstances, it's better to invest now in educating a robot to perform a task rather than later.

The Robotics Institute (RI) at Carnegie Mellon University has created an algorithmic planner to assist humans and robots distribute duties.

"Act, Delegate, or Learn" (ADL) is a planner that evaluates a list of responsibilities and determines how to best allocate them. Three inquiries were made by the researchers: When is it appropriate for a robot to take action in order to finish a task? When is it appropriate to entrust a work to a human? When is it appropriate for a robot to master a new skill?

“There are costs associated with the decisions made, such as the time it takes a human to complete a task or teach a robot to complete a task and the cost of a robot failing at a task,” Shivam Vats, the principal researcher and a Ph.D. student at the RI, explained.

“Given all those costs, our system will give you the optimal division of labor.”

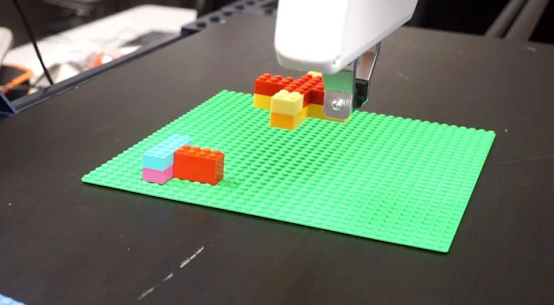

The team's findings might be useful in manufacturing and assembly facilities, package sorting, or any other setting where people and robots interact to execute several tasks. Researchers used situations where humans and robots had to put blocks into a peg board and arrange elements of various shapes and sizes made of LEGO bricks to evaluate the planner.

|

| A robot stacks LEGO bricks during simulations of the ADL planner. Robotics Institute researchers have developed an algorithmic planner that helps delegate tasks to humans and robots. |

Even when robots are part of the team, using algorithms and software to decide how to delegate and divide labor is not new. However, this is one of the first studies to include robot learning into its reasoning.

“Robots aren’t static anymore,” Vats stated. “They can be improved and they can be taught.”

A human would often manually move a robotic arm in manufacturing to educate the robot how to execute a task. Teaching a robot takes time and requires a significant initial investment. However, if the robot can acquire a new talent, it may be advantageous in the long term. Determining whether it is preferable to train a robot vs assigning the duty to a human is part of the challenge. This necessitates the robot predicting what additional tasks it will be able to do after learning a new one.

Given this data, the planner turns the issue into a mixed integer program — an optimization program often used in scheduling, production planning, and network design — that can be solved quickly using commercial software. In every case, the planner outperformed standard models and cut task completion costs by 10% to 15%.